Synopsis: Here’s a look at some easily made tools that will make life easier in the shop: the dovetail marker, the glue-bottle wrench, a drawer opening strap, pins for centering a tabletop, spacers for aligning drawer parts when cutting dovetails, and a foolproof depth stop for drilling.

Some tools in your shop can’t be bought. Or don’t need to be. Many are specific to your needs and operations. Certain ones might be used only occasionally, but are handy to have when needed, just to make life a bit easier. They can be made with a minimum of fuss and equipment, often with just scraps put to good use.

Dovetail marker

You can purchase a metal dovetail marker, but in half an hour or less you can make your own. Moreover, you can make a fleet of them at different angles if you wish.

Quick to make. Starting with an over-length piece of stock, establish the shoulders on the table saw. Then cut the cheeks at the bandsaw. While the stock is still long, pencil in your angle lines, and then cut them freehand on the bandsaw. A handsaw would handle these tasks as well. Finally, crosscut the marker and refine the angles with a hand plane or sanding block.

|

|

Glue-bottle wrench

Glue-bottle wrench

Who hasn’t cursed their glue bottle when all the dried glue makes it hard to open the nozzle? A shopmade wrench kept near the bottle takes minutes to create and makes for easy opening every time. I’ve made a few wooden wrenches, 3⁄8 in. by 1 in. by 4 in., out of scrap wood. Drill a 9⁄16-in. hole near one end, then make two parallel cuts with a saw and it’s done.

Drawer opener

When fitting flush doors or drawers, it’s difficult to get them out of their openings before the pulls are attached. To solve the problem, I have a 1-in. by 5-in. piece of 25-gauge hose clamp strap with the last inch bent back and hammered, then opened slightly. I force it between the drawer and the divider until the bent piece springs back, then pull the drawer out. Alternatively, an L-shaped Allen wrench can be used for the same purpose; just select one smaller than the drawer’s gap.

Centering pins

To keep your tabletop in place when you’re attaching its base, these quick-to-make centering sticks are invaluable. They are 1⁄4-in. or 3⁄16-in.-dia. brass welding rods, cut to about 6 in. and sharpened. With the top and base upside down, I align the center of the base with the centerline of the table, and hammer in the one centering rod at each end of the base to keep it from shifting while I mark the rest of the screw holes using an awl. A 20d or 30d nail would also work.

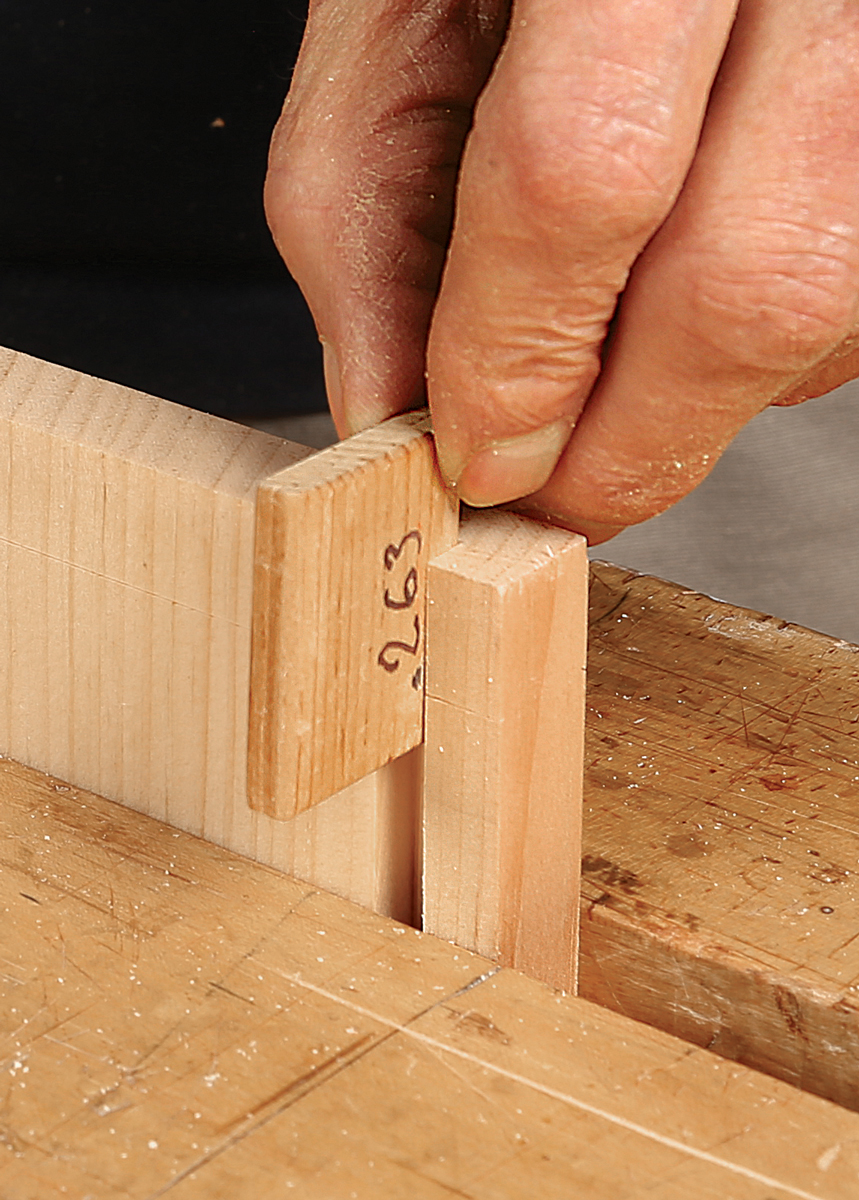

Alignment spacers

Whether you’re cutting pins or tails first, when you transfer one to the other it’s vital that the grooves for the drawer bottom line up perfectly so they will run uninterrupted all the way around the drawer box. Simple wooden spacers are an easy way to solve the dilemma.

Consistent depth stop

You never want to accidentally drill your shelf holes through the cabinet side. A simple, drilled cylinder that slides over the drill bit and stops the cut at the right depth is a no-mistake gadget for the task.

Drill and trim to length. Clamp your dowel tightly in a hand screw, and drill a hole the same size or slightly larger than the diameter of the intended drill bit. The hole you drill doesn’t have to go all the way through the dowel. Then cut the dowel to length based on the desired depth of hole. You can fine-tune the depth of the holes you’ll be drilling by trimming the stop or adding washers.

From Fine Woodworking #308

From Fine Woodworking #308

To view the article, please click the View PDF button below.

Chris Becksvoort, the dovetail master at work

Shopmade Cutting Gauge

Custom Scrapers for Custom Work

Sign up for eletters today and get the latest techniques and how-to from Fine Woodworking, plus special offers.

Download FREE PDF

when you enter your email address below.

View PDF