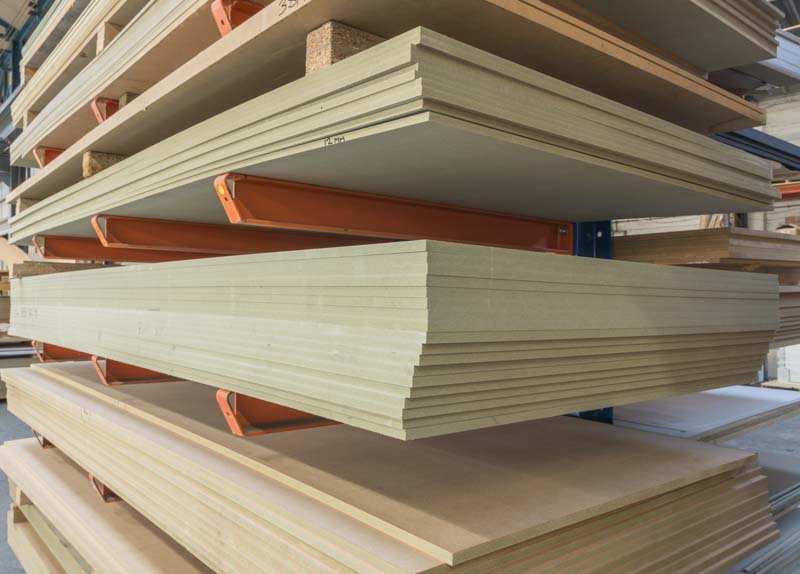

MDF is a real wood alternative used in modern construction and furniture making. Learn more about what MDF is and when to use it for your home improvement projects.

Understanding MDF Composition

MDF has numerous advantages over other types of engineered wood. Even though people often mistake it for particleboard, its manufacturing process is slightly different.

What MDF Stands For

The acronym MDF stands for medium-density fiberboard. Invented in 1925 by William Mason, it wasn’t patented until the 1960s. It wasn’t mass-produced until it became popular in the 1980s.

Manufacturing Process

Medium-density fiberboard is manufactured by combining uniform grains of dehydrated wood and pressing them together under high temperatures. Production is similar to particleboard and OSB (oriented strand board), but MDF uses finer particles that result in a smoother, denser product.

Types of MDF

An extremely versatile building material, MDF comes in various dimensions, including sheets and boards. Choose from several types, depending on the type of project you’re working on.

| Type of MDF | Description | Best for |

| Standard MDF | MDF with a regular density | Visible applications, trim, furniture, doors, partitions |

| Ultralight MDF | Lightweight with a consistent density | Non-structural applications |

| Moisture-resistant MDF | Designed for use in high-moisture areas | Bathrooms and kitchens |

| Fire-rated MDF | Treated with fire retardants for increased fire-resistance | Often used in public buildings that must adhere to stricter fire codes |

| Low-formaldehyde MDF | Made with lower levels of formaldehyde to reduce issues with off-gassing | Homes and buildings where environmental air quality is a concern |

| Exterior-grade MDF | Designed with enhanced durability against weather and insect exposure | Outdoor applications that require a material resistant to moisture, fungus, and insects |

Pros and Cons of Using MDF

While MDF lumber is an economical choice for many home construction and DIY projects, it’s not suitable for all applications.

Advantages

There are many advantages of medium-density fiberboard, including its versatility and availability, which make it a top choice for a wide range of projects. Here are the top reasons:

- Affordability–MDF is cost-effective compared to real wood.

- Strength–MDF doesn’t warp, crack, or swell as easily as other types of engineered wood.

- Smooth surface for finishing–MDF readily accepts paints, finishes, and laminates.

- Easy to use–MDF is easy to cut, shape, and work with.

- Eco-friendly properties–MDF is made from leftover and recycled wood, making it highly renewable.

- Consistent quality–MDF performs predictably due to its uniform density and structure.

Disadvantages

While medium-density fiberboard has several advantages, you should be aware of the following disadvantages:

- Weight and density–MDF is denser and heavier than real wood, so it may require more support.

- Limited structural strength–Although heavier than real wood, it has limited load-bearing capacities.

- Manufactured with formaldehyde–MDF products may release formaldehyde, impacting indoor air quality.

- Challenging to nail and screw–Fasteners don’t work the same with medium-density fiberboard as they do with real wood or plywood.

- Dulls cutting tools faster–The strong resins in medium-density fiberboard will blunt your cutting tools more quickly.

MDF vs Real Wood: A Comparison

Comparing medium-density fiberboard to real wood can be tricky because there are many types of wood. When choosing the right one for your project, compare MDF to different wood species, considering cost, durability, and appearance.

Medium-Density Fiberboard vs Solid Wood

Take a look at how it compares to natural, solid wood.

Cost Comparison

Compared to real wood, medium-density fiberboard is a budget-friendly option. However, it’s important to consider that some specialty MDF boards may cost more than inexpensive types of natural wood.

For example, low-formaldehyde, fire-rated, and exterior-grade MDF products may cost considerably more than inexpensive lumber.

Durability and Longevity

Innovations in manufacturing have led to engineered wood products that compete with real wood in durability and strength. Medium-density fiberboard is stronger than many types of wood but has a limited load-bearing capacity, so it depends on the application.

Finish and Appearance

It’s hard to beat the look of real, natural wood, but medium-density fiberboard has some advantages over real wood when it comes to appearance. For one, it offers a much smoother surface for painting and finishing. It also doesn’t have knots and variations like real wood, making it easy to cut and shape.

MDF vs Plywood

Discover how medium-density fiberboard measures up to plywood.

Strength and Durability

Regarding strength and durability, plywood offers superior structural integrity and moisture resistance than medium-density fiberboard. Even though MDF is heavier, it’s softer, less rigid, and more likely to sag than plywood. Plywood is harder and less likely to dent or chip with rough handling.

Cost Considerations

Medium-density fiberboard is usually less expensive than plywood. The price of each varies depending on thicknesses, dimensions, and grade, but MDF is typically more affordable than plywood.

Versatility

While both products are excellent for indoor applications, plywood offers greater versatility when it comes to outdoor uses. Even though there are exterior-grade MDF products, they aren’t as durable as plywood.

When to Use MDF

When used for interior applications like cabinets, furniture, and trim, MDF is more affordable and easier to customize.

Interior Applications

From decorative paneling and trim to cabinetry and furniture, medium-density fiberboard is an affordable, versatile, and durable option.

Cabinet Making

Most new kitchen cabinets consist of both solid wood and MDF. Because it’s less likely to warp than solid wood, MDF is the material of choice for cabinet doors.

Furniture Construction

Builders frequently use medium-density fiberboard in fine furniture construction, including bookcases, tables, and media cabinets. It is easy to cut and shape and can be finished with various veneers, laminates, and paints to achieve a stylish, durable finish.

Decorative Paneling

MDF wall panels offer a durable and versatile way to achieve a polished, finished look on walls, wainscoting, and cabinetry. From beadboard to sculpted MDF panels, hundreds of styles are available for decorative wall paneling to personalize your space.

Exclusions and Caution

Medium-density fiberboard isn’t suitable for all woodworking projects, however. Learn when it’s best not to use it.

Outdoor Usage

Although there are exterior-grade MDF materials, they aren’t the best choice for outdoor usage. Exterior-grade MDF products provide limited strength. You should waterproof them for the best results.

High-Moisture Environments

Standard medium-density fiberboard isn’t suitable for high-moisture environments like your kitchen or bathroom. Both of these areas frequently have problems with leaks, humidity, and water exposure, leading to swelling and warping of MDF.

Tips for Using Medium-Density Fiberboard

Follow these tips when using MDF products in your home improvement projects.

Cutting and Shaping

One of the best qualities of medium-density fiberboard is its uniform consistency, which makes it easy to cut and shape. However, it’s made with resins and wax that dull your cutting tools much quicker than other types of wood.

When using it, take proper safety precautions by ensuring your bits and blades are sharp. It is made with formaldehyde and adhesives, so minimizing dust and protecting your lungs is critical for your health and safety.

Speaking of cutting MDF, check out our Best Router Table Reviews list!

Finishing and Painting

You can finish medium-density fiberboard in various ways to enhance its durability and appearance. From laminating to painting, here are the top ways to finish MDF:

- Paints

- Veneers

- Laminates

- Varnishes

- Stains

- Melamine coatings

- Epoxy resin coatings

- Metallic finishes

- Chalkboard or whiteboard paints

Sanding MDF before painting or coating will help you achieve a smooth finish.

Maintenance and Care

Whether you use medium-density fiberboard for wall paneling, furniture, or cabinetry, you must take care to avoid moisture damage. Keep it dry, and avoid using a lot of water if you have to wash it.

Repair minor damages to MDF, such as baseboard damage, using wood filler or Bondo. You can sand and paint it to match the surrounding area.

FAQs About What MDF Is

Is MDF Real Wood?

It uses real wood fibers, but it’s an engineered alternative to real wood. For most applications, it is better than regular plywood or particleboard, two other engineered wood types.

Can It Be Used Outdoors?

You cannot use standard medium-density fiberboard outdoors because it’s prone to moisture damage. In some applications, exterior grade MDF is acceptable for outdoor use, but you should waterproof it. Even so, it won’t be as structurally sound as real wood.

Is MDF Environmentally Friendly?

MDF is one of the most eco-friendly building materials you can use. Wood fibers are renewable, and MDF is made from leftover and recycled wood. Since you can recycle it at the end of its lifespan, it’s a highly sustainable product.

How Does It Compare to Particleboard?

It is quite similar to particleboard, but it’s denser and stronger. While particleboard comes from sawdust, MDF uses fine particles of wood fibers pressed together more densely than particleboard, giving it a smoother consistency and finish.

Can I Stain MDF?

While it is sustainable, people often paint it because it doesn’t have real wood grains. Since it’s dense, it doesn’t absorb stain like wood does, so gel stains are the best type of stain to use on MDF.