The bolt carrier group is the heart of any AR-style firearm, we discuss how to find the best BCG for your needs.

The beating heart of any AR-style firearm is the bolt carrier group, the assembly that includes the bolt carrier, bolt, extractor and ejector. If there is one component you should spend money on to ensure reliable function, the BCG is it.

So, let’s talk about what bolt carrier groups are, what they do, why it’s important to get a quality one, some important features to pay attention to and finally the best BCGs you can buy today.

What Is A Bolt Carrier Group?

The bolt carrier group of a semi-auto rifle is the assembly that puts a cartridge into the chamber, extracts/ejects it after firing, cocks the hammer and loads the next round. Any semi-automatic rifle has one, though their exact design varies depending on the firearm.

However, given the supreme popularity of AR-style guns today, the mention of a bolt carrier group or BCG typically refers to that of the AR-15 or AR-10. That’s what we’ll focus on in this article.

What Parts Comprise An AR Bolt Carrier Group?:

- Bolt

- Bolt carrier

- Bolt cam pin

- Extractor

- Ejector

- Gas key

- Gas rings

- Firing pin

- Firing pin retaining pin

Those are the major parts at least, but there are also some small pins, screws and springs that hold everything together and ensure proper function.

Given the central role that the BCG plays in the cycling of self-loading firearms, it’s easy to describe it as the beating heart of the machine. This is why choosing a quality one is such an important aspect of building a reliable and long-lasting AR.

Metallurgy

There are several different types of steel used to make bolt carrier groups. Sometimes you’ll find that the carrier and bolt are made of the same metal, but that’s not always true.

The two most common types are Carpenter 158, a proprietary chrome-nickel steel alloy, and 9310, a chrome-nickel-molybdenum (cro-nickel-moly) steel with similar material properties. 9310 is a good steel on its own, but it’s slightly harder than Carpenter 158 and as a result, requires an assiduous heat treatment to avoid becoming brittle.

Some other common bolt carrier group steels include 8620 steel, a chrome-nickel-manganese alloy normally reserved for the carrier itself, and S7 tool steel.

S7 is a hard tool steel, but like 9310 it requires a rigorous heat treatment or it will become brittle. Low-quality S7 steel tools are known for shorter working lives as they don’t tolerate wear.

So, which is the best for a bolt carrier group?

Well, before anything else, the following should be addressed: the major stress points in the bolt carrier group are all found in the bolt. Specifically, the radial lugs and the bolt cam pinhole.

Issues with the carrier itself, outside of manufacturing defects, are rare.

Therefore, from my experience, what matters most is the type of steel used to make the bolt itself. The answer is Carpenter 158. That’s been the military specification steel for decades, and C158 bolt heads are known for lasting longer than anything else.

Bolts made of 9310 steel are known for having a slightly higher failure rate unless the manufacturer pays good attention to proper heat treatment or uses a proprietary design that reduces mechanical stress at key points. Ergo, be wary of lower-cost BCGs with a 9310 bolt, but they can work fine when properly manufactured.

Finishes

There are many different bolt carrier group finishes and coatings, but the most common are nitride, phosphate, chrome and nickel-boron. Parkerized bolt carrier groups are also somewhat common, as well as DLC (diamond-like coating) and titanium-nitride finishes.

Nitriding is the cheapest and is accomplished by putting a heated part into either a nitrogen-rich salt bath or a gas chamber, typically filled with ammonia, which causes the nitrogen to diffuse throughout the surface of the metal and hardens the outside. It’s the cheapest, so it shouldn’t be surprising it’s also the weakest.

For phosphate finishes, a heated part is placed in a bath of a phosphate compound (typically with a high concentration of phosphoric acid with mineral salts) which causes the phosphate and mineral salt particles to likewise bond with the surface of the steel. Parkerizing is also a type of phosphate finish but it uses a specific process.

Phosphate is the military-specification (mil-spec) finish, and it tends to last the longest. That said, phosphate and nitride finishes don’t have a high natural lubricity and therefore require the regular application of lubrication to ensure proper function. They are somewhat corrosion-resistant, but should still be cleaned periodically as part of maintenance.

Chrome finishes are an electroplating process that puts a layer of chrome over the entire part. Chrome has better lubricity and corrosion resistance than nitriding or phosphating, but it’s also more difficult to do and results in chromed BCGs being more expensive.

Nickel-boron is much like chroming, just with a different process (electroless plating) with most of the same benefits. It possibly has even greater lubricity and corrosion resistance than chrome. However, it is also much cheaper to do and as a result, is often offered on lesser-quality bolt carrier groups. There’s nothing wrong with nickel-boron finished BCGs themselves, you just need to ensure that it was done correctly by buying a reputable brand.

Diamond-like Coating, or DLC, is a carbon coating with a molecular lattice/crystalline structure. Like a diamond, it is hard and wear-resistant with good lubricity and corrosion resistance.

Titanium-nitride coatings (TiN) are a ceramic coating type that are baked on to coat the carrier group. They’re known for their gold-like appearance and have excellent wear resistance and lubricity, but they’re also vulnerable to accelerated wear if heated for long periods.

So, what’s the best finish? My take is that it depends on how you plan to use the AR. If durability and longevity are your main concerns, phosphate and chrome are the best for hard use. That’s what the military uses today and what they used to use with M16s, respectively, so they have a proven track record. If you plan on using your rifle or carbine for competitions or casual fun, the high lubricity of TiN coatings can be a good choice too.

When it comes to BCG finishes, I’ve found the reality is that they all work, but some will survive more abuse longer, while others have different advantages like requiring less frequent lubing or facilitating easier cleaning. Like everything else, you get what you pay for, so the only type to really avoid are bottom-of-the-barrel discount parts that likely have dubious QC with their coating processes.

Profiles

When it comes to bolt carrier group profiles, there are three general styles: semi-auto, full auto and low-mass/lightweight.

Semi-auto bolt carriers have an asymmetrical tail, as the extra material on a full auto bolt carrier is there to engage the auto sear for full-auto fire. Semi-auto carriers are rarer, however, and a full-auto carrier makes no difference in the function of a semi-auto AR.

Lightweight bolt carriers are skeletonized to reduce the mass, which, contrary to popular belief, does not reduce recoil. What it does do is reduce the inertial force of the bolt carrier.

However, lightweight BCGs have long been known for being temperamental. Therefore, a low-mass carrier is not a good idea unless you’re going to fine-tune a race gun with a muzzle device and gas system for optimal reliability.

So, unless you’re going this route, it’s best to stick with a conventional full-auto or semi-auto carrier.

What To Look For In A Quality Group

So, besides the basic features, materials and finish, what do you need to look for to ensure you’re getting a high-quality bolt carrier group?

I always like to start with a reputable manufacturer with a good track record. If you’re getting a mil-spec bolt, find one that makes BCGs for the military.

Here’s what you need to look for:

Stick to bolt carriers that have MPI and HPT done by the factory.

MPI, or magnetic particle inspection, is an industrial testing process where an electromagnetic field is used to detect any defects in a part. It detects non-uniform materials which indicates flaws in the material or finish.

High-pressure testing, or HPT, is where the manufacturer proof-tests the part by shooting a proof load loaded to over 77,000 psi of chamber pressure. This proves the part is capable of handling stress.

Shot peening is also a must. Shot peening is a process where a part is subjected to media, basically BBs, to apply stress to the material. This process essentially compresses the material and induces just the right amount of stress to ensure that the part can endure the stresses of real operation.

Lastly, you want to ensure the gas key is securely attached to the carrier. The gas key is where gas meets the carrier to push it rearward to cycle the firearm. Military specifications and general wisdom require the gas key to be staked.

When the gas key is properly installed using good fasteners, thread locker and the proper amount of torque, many respected armorers claim that this is enough to keep the key in place and prevent the screws from backing out. The same people also claim that even staked gas keys can be loose or broken if otherwise not properly installed. The choice is yours, but whether your gas key is staked or not is less important than whether it was correctly installed by a reputable builder. Whatever method is used, you just want the key and carrier to be securely mated so nothing comes apart when you need the gun to work.

Our Bolt Carrier Group Picks:

Sons of Liberty Gun Works Bolt Carrier Group 5.56

SPECS:

- Bolt Material: Carpenter 158

- Carrier Material: 8620 Carpenter

- Bolt Finish: Manganese Phosphate

- Carrier Finish: Manganese Phosphate

- Profile: Full Auto

- Weight: 11.4 Ounces

- MSRP: $189.99

This is my go-to for a hard-use AR build. It features a Carpenter 158 steel bolt and an 8620 steel carrier with Grade 8 fasteners and a full-auto profile. SOLGW subjects every carrier to MPI, HPT and shot peening. If you only want to buy one and never worry about it again, then this is your bolt carrier. MSRP is $189.99, but they can be found elsewhere for less.

JP Enterprises LMOS w/ JP Enhanced Bolt

SPECS:

- Bolt Material: SAE 9310

- Carrier Material: 416 Stainless

- Bolt Finish: DLC

- Carrier Finish: QPQ

- Profile: Low-Mass/Lightweight

- Weight: 8.8 Ounces

- MSRP: $375

JP Enterprises is one of the go-to manufacturers of competition AR parts, and its Low Mass Operating System (LMOS) carrier is a no-brainer choice for a race gun. JP Enterprises strongly advises pairing it with a muzzle device and an adjustable gas block for the best results.

The LMOS carrier features a QPQ finish and the bolt has a DLC finish for extra lubricity, and the JP Enterprises Enhanced Bolt has rounded radial lugs to decrease wear as well as some other upgrades. Besides .223/5.56mm, the bolt can also be ordered for 6.5mm Grendel, 6.8mm SPCII and .204 Valkyrie. MSRP is $375.

Bootleg Four Position Adjustable Carrier

SPECS:

- Bolt Material: S7 Tool Steel

- Carrier Material: S7 Tool Steel

- Bolt Finish: Lithium Isonite

- Carrier Finish: Lithium Isonite

- Profile: Full Auto

- Weight: 10.8 Ounces

- MSRP: $199.99

Bootleg’s adjustable carrier has a four-position adjustment in the gas vent holes, allowing you to tune the amount of gas going into the rifle. I recommended these BCGs for people who run suppressed rifles or who are trying to tune an under- or over-gassed rifle.

Made of durable S7 Tool Steel and featuring a lithium isonite coating and a full-auto carrier profile, it should keep up with the best of them. If there’s one downside, it’s Bootleg is unfortunately tight-lipped about its QC process. At a minimum, we know that their BCGs are particle inspected. MSRP is $199.99.

Microbest C158 Bolt Carrier Group Chrome

SPECS:

- Bolt Material: Carpenter 158

- Carrier Material: 8620

- Bolt Finish: Hard Chrome

- Carrier Finish: Hard Chrome

- Profile: Full Auto

- Weight: 15 Ounces

- MSRP: $154.95

Microbest manufactures quality BCGs at an attainable price point, and they’re known to be an OEM for a lot of rifle brands that are held in high regard.

An 8620 carrier, Carpenter 158 bolt in a full-auto profile, with MPI, HPT and shot peening done by the factory. They’re available with nitride and phosphate finishes as well, but considering the hard chrome option only costs a bit more, that’s probably the option to go with. MSRP is $154.95.

Sharps Rifle Company XPB

SPECS:

- Bolt Material: S7 Tool Steel

- Carrier Material: S7 Tool Steel

- Bolt Finish: DLC

- Carrier Finish: DLC

- Profile: Full Auto

- Weight: 11.2 Ounces

- MSRP: $219.99

Sharps X-Treme Performance Bolt Carrier Group (XPB) is an improved bolt carrier group design, available with seven bolt caliber options besides the standard 5.56.

The carrier and bolt are S7 tool steel, shot-peened before finishing and given a 24-hour heat treat. The bolt lugs are also radiused to eliminate the most common wear and breakage points of AR-15 bolt lugs. MSRP is $219.99.

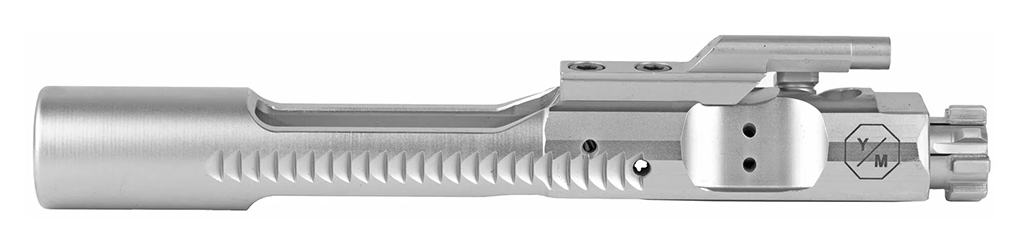

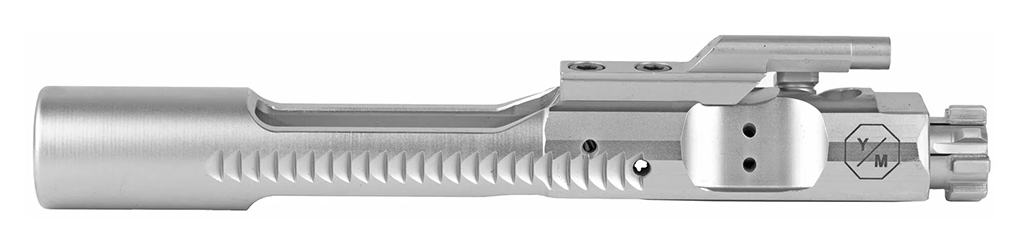

Young Manufacturing M16 Chrome BCG w/ HMB Bolt

SPECS:

- Bolt Material: 9310

- Carrier Material: 8620

- Bolt Finish: Hard Chrome

- Carrier Finish: Hard Chrome

- Profile: Full Auto

- Weight: Not Listed

- MSRP: $274.95

Young Manufacturing, known for its national match bolt carriers for service rifle competitors, adds some key improvements to enhance longevity. The carrier key features a recoil lug (and recoil lug recess on the carrier) for reducing shear stress on the carrier key screws, and the HMB Defense bolt has a cam pin recess (instead of thru-hole) and shorter cam pin to eliminate cam pin hole breakage.

The carrier is 8620 steel with a full-auto profile, with a 9310 bolt by HMB Defense. The bolt and carrier are MPI, HPT, shot-peened and chromed in-house by Young. MSRP is $274.95.

AO Precision Phosphate Bolt Carrier Group

SPECS:

- Bolt Material: Carpenter 158

- Carrier Material: 8620

- Bolt Finish: Manganese Phosphate

- Carrier Finish: Manganese Phosphate

- Profile: Full Auto

- Weight: 11.52 Ounces

- MSRP: $159.95

AO Precision is the OEM for several AR-15 manufacturers, including FN and Colt. Their white-labeled BCGs for other companies will cost you a lot, but AO-branded BCGs won’t. For the budget-conscious, don’t bother with anything else; more bang for the buck is not available.

The BCG is a mil-spec bolt carrier group with a Carpenter 158 bolt, 8620 carrier, a staked carrier key with Grade 8 fasteners and a chrome-lined bolt channel. HPT, MPI and shot peening are done at the factory. The best part is they can be easily found for $100 or less online.

Get On Target With The AR:

Next Step: Get your FREE Printable Target Pack

Enhance your shooting precision with our 62 MOA Targets, perfect for rifles and handguns. Crafted in collaboration with Storm Tactical for accuracy and versatility.

Subscribe to the Gun Digest email newsletter and get your downloadable target pack sent straight to your inbox. Stay updated with the latest firearms info in the industry.